Durable insulation molds include a series of molds made of polystyrene foam that are quickly installed and ready for concrete.

After the foundation is laid and the exact location of the walls is determined, the molds are installed and the reinforced concrete is put in place and then filled with laminate concrete. In this system, due to the non-use of columns, all walls are designed to be load-bearing, which is why the designed structure has a good resistance to the lateral loads.

One of the most desirable features in this formatting is the use of multi-purpose retainers, which is a great tool for amateurs to get to the place they want, without spending too much time.

The simple molding and cutting of molds make it possible to install the installations and other necessary building components as easily as possible.

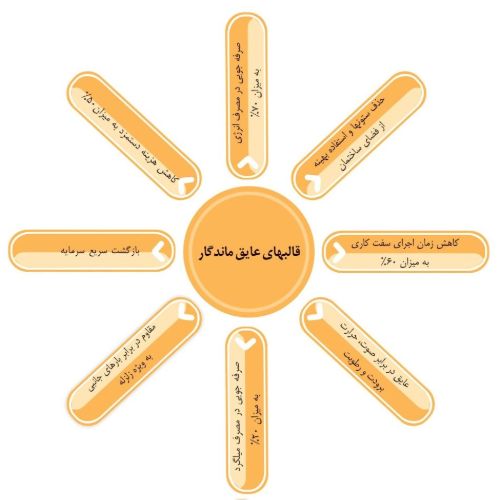

Benefits of durable insulation molds:

- ۱% energy saving

- A 4-5% reduction in the amount of time in framework as a result of your pay cut

- ۲-۵% savings on rebar use

- Rapid return on capital and increased construction number by mass builders

- Remove columns (even possible) and make optimum use of building interiors

- Insulation for sound, heat, cooling and humidity

- No restrictions on concrete in winter

- Resistant to lateral loads, especially during earthquakes

Time is one of the most important factors in managing a construction project. In addition, in constructing structures in this way, the most attention is paid to this system because of the low energy input, and due to the high cost of energy, building designers are looking for a system that can be operated in less time.

After the concrete foundation is laid, it is time to build the walls. Once the exact location of the walls has been determined, the molds will be installed and the installations will fit into place. One of the most desirable features of this type of molding is the use of multifunction retainers, which is a great tool for placing amateurs in the desired location without spending too much time.

The simple molding and cutting of molds make installation and other necessary building components as easy as possible.

ICF molds include a series of molds made of polystyrene foam that are quickly installed and ready for concrete. After the molds are installed, the inside is filled with laminated concrete. In this system, due to the non-use of columns, all walls are designed as load bearing and therefore the designed structure has good resistance against the lateral loads.

Given all of the above, and being easy to mold, precision and at the same time ease in reinforcing the walls, a small cross-section suitable for concreting has made this system one of the fastest modern construction systems, so that 145 square meters of building will be constructed within three days.

High speed of molding, reinforcement and even concreting due to the use of self-compacting concrete

Fully- integrated concrete components and high resistant structures for lateral loads such as wind and earthquake and etc.

Providing suitable curing conditions for concreting contents of molds due to proper polystyrene coating

No need for release material due to permanent installation of molds

Convenient placement and ease of reinforcement

Easy shipping of molds

Overview of ICF system

The durable insulation molding system basically consists of permanent molds that are used to concrete and build reinforced concrete walls and are part of the wall after concreting.

The molds in this system are expanded from polystyrene.

In this system, the components are used as a permanent (permanent) mold for structural concrete, including load-bearing or non-load-bearing, below the ground level or on the ground surface.

These parts are used for making beams, portals, outer and inner walls, foundations and reinforced concrete or concrete retaining walls.

These parts remain in place after concrete is poured and processed.

Procedure:

۱. Foundation preparation:

The foundations of ICF systems are mainly strip or wide, similar to conventional reinforced concrete structures, which should also include dowel bars.

۲. Wall placement:

For precise placement of the blocks, an iron or galvanized angle is used.

۳. Place the blocks on the foundation so that their male bulge are upward and the dowel bars are passed through the blocks.

We also put the male and female head and bottom of blocks together and place the corners in the same way.

Adjusting the length of the blocks is also possible with manual saws.

۴. Reinforcing inside the blocks:

After each row is arranged, one or two rows of horizontal rebar are also placed on the middle interface of the blocks based on the structural map and we attach the reinforcement together using a wire.

۵. Deploying retaining wall

After blocks are installed, retaining walls should be installed at regular intervals to secure the wall after concrete installation, at the time of concreting. At the same time, the platforms are installed for ease of concreting. Stability of these platforms is provided by the retaining wall structure.

۶. Operating the openings:

The openings at the door and the windows are also installed with the block in accordance with the maps, so that they are properly operated when concreting.

۷. Aligning:

After finishing the walls and installing the retaining walls, the walls are aligned by a jack.

۸. Concreting:

Concreting in the walls should be in uniformly thick horizontal layers, and each layer should be fully compacted before pouring the next layer. The rate and speed of the concrete should be in such a way that when the new layer is poured, the previous layer is still plastic.

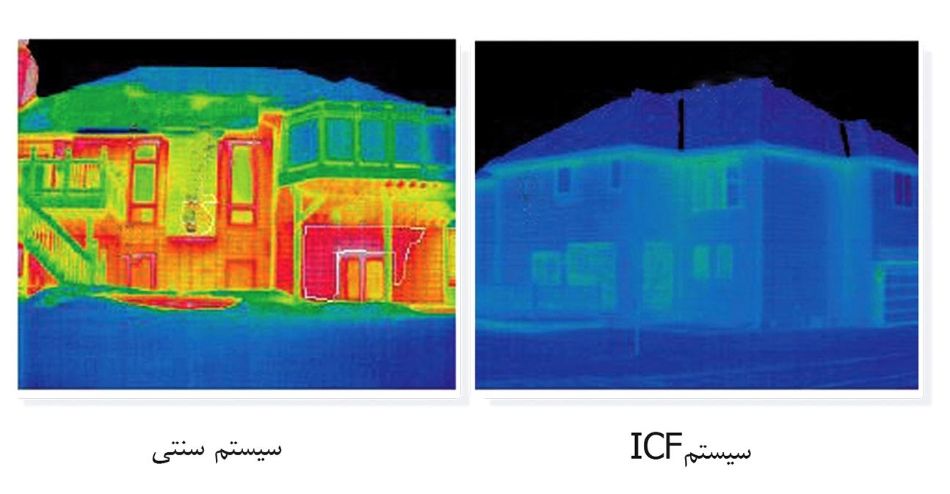

Benefits of ICF System in terms of Thermal Behavior:

In general, the ICF building system has the following advantages in terms of thermal behavior:

High thermal resistance due to the use of two layers of polystyrene thermal insulation, each of which typically has a thickness of 1 cm

Appropriate sealing of joints and air locking of the wall and consequently negligible amount of air penetration and heat exchange caused by it

The uniformity of the inner surface temperature of the wall, due to the presence of an inner layer with thermal insulation and the absence of significant thermal bridges

Great transformation and resurrection in the building industry

-

The benefits of durable insulation molds

- ۷۰ Energy-saving Consumption

- ۴۰-۵۰% reduction in the framework time (as a result of reduced wages)

- ۲۵-۳۰% savings on rebar usage

- Rapid return on capital and increased construction number by mass builders

- Remove columns if possible and make optimum use of the interior of the building

- Sound, heat, cooling and moisture insulation

- No restrictions in concreting in winter

- Resistant to lateral loads, especially earthquakes

Traditional system

Durable insulation molds include a series of molds made of polystyrene foam that are quickly mounted and prepared for concreting.

ICF durable insulation molds include molds made of polystyrene foam that are quickly installed and prepared for concreting.

After the foundation is laid, and the exact location of the walls is determined, the molds are installed and the reinforcement is designed in place and filled with smooth concrete. In this method, due to the non-use of columns, all walls are designed to be load bearing and therefore the designed structure has a good resistance to lateral loads.

One of the most desirable features in this type of molding is the use of multifunctional space retainers, which are a great tool for placing reinforcement in the desired location without the need for time.

The simple molding and molding of the ICF-type molds allows for the simplest possible installation and other building attachments.